Emergency! Fanuc Timeout Line Halted Production? Get Immediate Help Here! - A Critical Examination

The emergency Fanuc timeout line, a critical component in manufacturing operations, poses complex challenges that require a comprehensive understanding of technical, operational, and human factors to ensure efficient production.

Technical Complexities

-

Installing and configuring Fanuc timeout lines demands specialized technical expertise.

-

Improper settings can lead to interruptions, delays, and safety hazards.

-

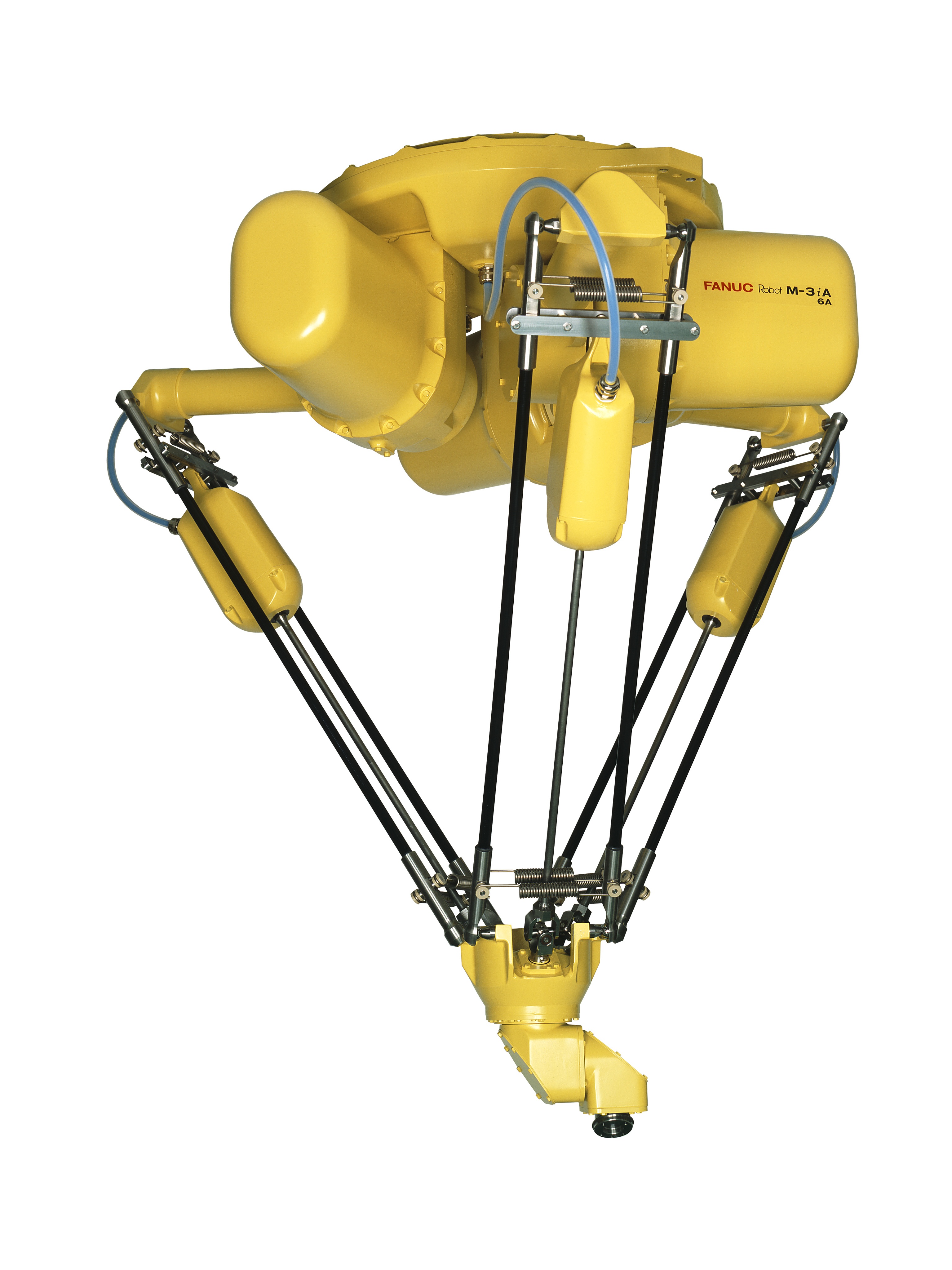

Fanuc timeout lines integrate with various machines and software systems.

-

Compatibility issues can cause communication errors and malfunctions.

-

Diagnosing and troubleshooting Fanuc timeout line issues require advanced technical skills.

-

Real-time monitoring tools help identify potential problems.

Operational Challenges

-

Timeout lines play a crucial role in maintaining production flow.

-

Improperly configured lines can create bottlenecks and reduce efficiency.

-

Fanuc timeout lines require effective material handling and inventory management.

-

Insufficient material supply or inefficient inventory control can lead to production delays.

-

Operators must be adequately trained to handle Fanuc timeout lines.

-

Errors due to lack of knowledge or skill can disrupt production.

Human Factors

-

Fanuc timeout lines involve moving machinery and electrical components.

-

Proper safety protocols must be implemented to prevent accidents.

-

Operators working on Fanuc timeout lines may experience stress and fatigue.

-

Ergonomic considerations and work-rest cycles are crucial for maintaining alertness and productivity.

-

Effective communication and collaboration among operators, supervisors, and maintenance personnel are essential for troubleshooting and resolving issues.

-

Clear communication channels and established response protocols are critical.

Perspectives and Scholarly Research

-

Engineering research focuses on optimizing Fanuc timeout line configuration and performance.

-

Studies have shown that proper installation and maintenance can significantly reduce downtime.

-

Operations management research examines the role of Fanuc timeout lines in production flow optimization.

-

Findings suggest that integrating these lines effectively improves efficiency and reduces waste.

-

Psychology and ergonomics research explores the impact of Fanuc timeout lines on operator safety and well-being.

-

Studies indicate that ergonomic modifications and training can enhance operator performance and reduce fatigue.

Implications for Manufacturing Operations

-

Investing in training programs and advanced monitoring technology can mitigate risks and improve line efficiency.

-

Establishing clear communication channels and fostering collaboration among staff ensures timely troubleshooting and problem-solving.

-

Regularly evaluating Fanuc timeout line performance and implementing continuous improvement measures can optimize production and reduce downtime.

-

Considering human factors in Fanuc timeout line design and operation promotes operator safety, reduces fatigue, and enhances productivity.

Conclusion

The 275 X 1.075 Mystery Solved! Experts React.

HBD Mode Driving You Crazy? This Fix Works Every Time

Unlock Fooocus Performance: Master Your Error Logs Today